Masa's Pastime - Taking it Step by Step

From junk-shop to haute horlogerie.

Interview with Masa (Masa & Co., Japan)

Adi: So your name is Masa, right? Full name?

Masa: Mm-hmm. My real name is Masaharu Nakajima. But everyone calls me Masa. Just call me Masa — that’s how everybody knows me.

Becoming a Watchmaker Through Frustration

Adi: You have a very interesting brand and history. Based on what I see, you started as a dealer in antique watches but became frustrated. What happened?

Masa: Yeah, you know, I started as an antique junk dealer — just by myself. But I had some watches. Then later I had more and more watch clients.

So I focused on vintage and antique watches. But the problem was: I couldn’t repair them myself. I had to ask local watchmakers. Most of them were very old. They couldn’t repair the watches well. They would say:

“These watches are too old. You can’t really use them anymore.”

Clients complained a lot. I got sick and tired of listening to that.

One night a watch was returned again, and I was so mad I thought I would break it. But when I opened the back, I saw the movement and thought:

“This is beautiful. Not bad at all.”

It was running sluggishly, but running. Since the client already returned it, I didn’t care if I broke it. So I disassembled it myself with simple tools, trying not to break anything. I cleaned everything with Zippo fluid. I started around 7 at night. When I looked up, it was morning. I assembled it — it didn’t run perfectly, but it ran.

That was the day I decided: “I have to learn this myself. No other choice.”

I bought as many books as possible (mostly from the U.S.), bought many tools, and taught myself. That was about 32–33 years ago. I started the shop in 1990, and began repairing around three years later.

From Antiques to Early Custom Wristwatches

Adi: So after that, you improved your watchmaking skills. How did you transition from repair work to eventually selling your own watches?

Masa: Back then, it was a very small business. I repaired every watch I sold.

About 25 years ago, Katsu, who is now our chief mechanic, joined me. He was very skilled.

Around 20-something years ago, we started making custom wristwatches from antique pocket watch movements — taking small pocket movements, making cases, turning them into wristwatches. People liked them.

We still make some of those.

The First Attempt at a “Manufacture” Movement

Masa: About 10 years ago I met a Swiss guy who was working for a big brand. He had three months in Japan, so I asked him: “Why don’t you design a movement for us? Someday we want to make our own.”

And he did — a good design.

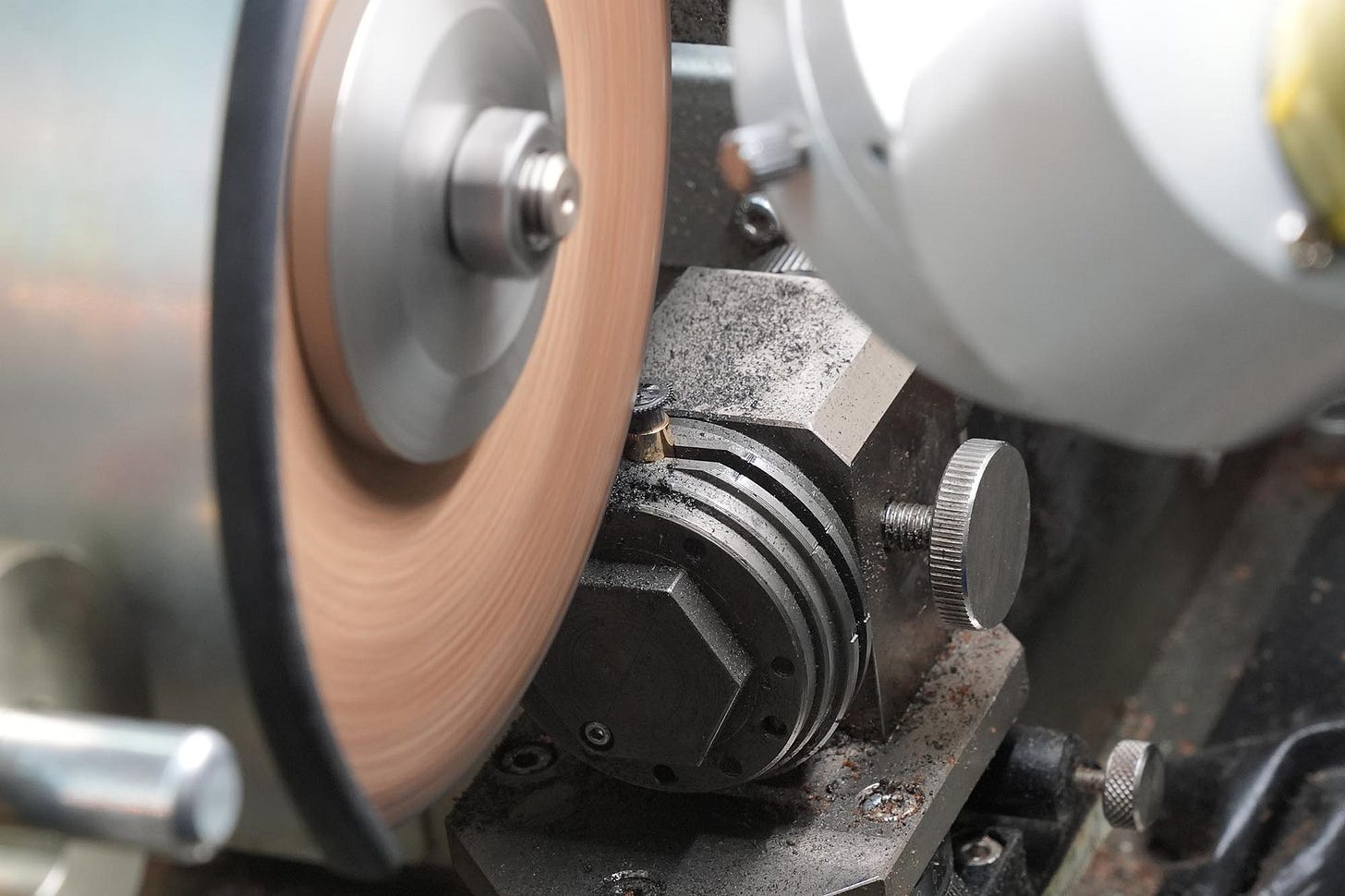

We were already making plates and wheels ourselves.

Then Philippe Dufour visited. I showed him the movement, about 60% done. He said: “This looks pretty good… but it doesn’t feel like it was made by Japanese guys.”

And of course — the design was by a Swiss guy.

After he left, I stopped that project. I apologised to the designer and said: “We must make a movement entirely by ourselves.” It took 10 years to complete what is now our in-house movement: MP1.

What It Takes to Make an In-House Movement in Japan

Adi: Most people don’t understand what it takes to make an in-house movement. What was the journey?

Masa: The hardest part was that I truly wanted to make everything here — in our workshop. If we bought ready-made escapements from Switzerland, it would be much faster.But I wanted everything made here.

That meant we had to learn to make:

Pinions

Escape wheels

Balance parts

All the critical components

The escapement was especially tough.

What parts are not made here?

Only these:

Hairspring

Mainspring

Jewels

Those are imported (Switzerland & Germany).

Everything else — 100% is made here for the MP1.

Design Philosophy — Three MP Series Models

Adi: What is your design philosophy for the MP watches you offer?

Masa: None of us are designers. I just make what I like — in the simplest way.

We have three MP models:

1. Soko-ku

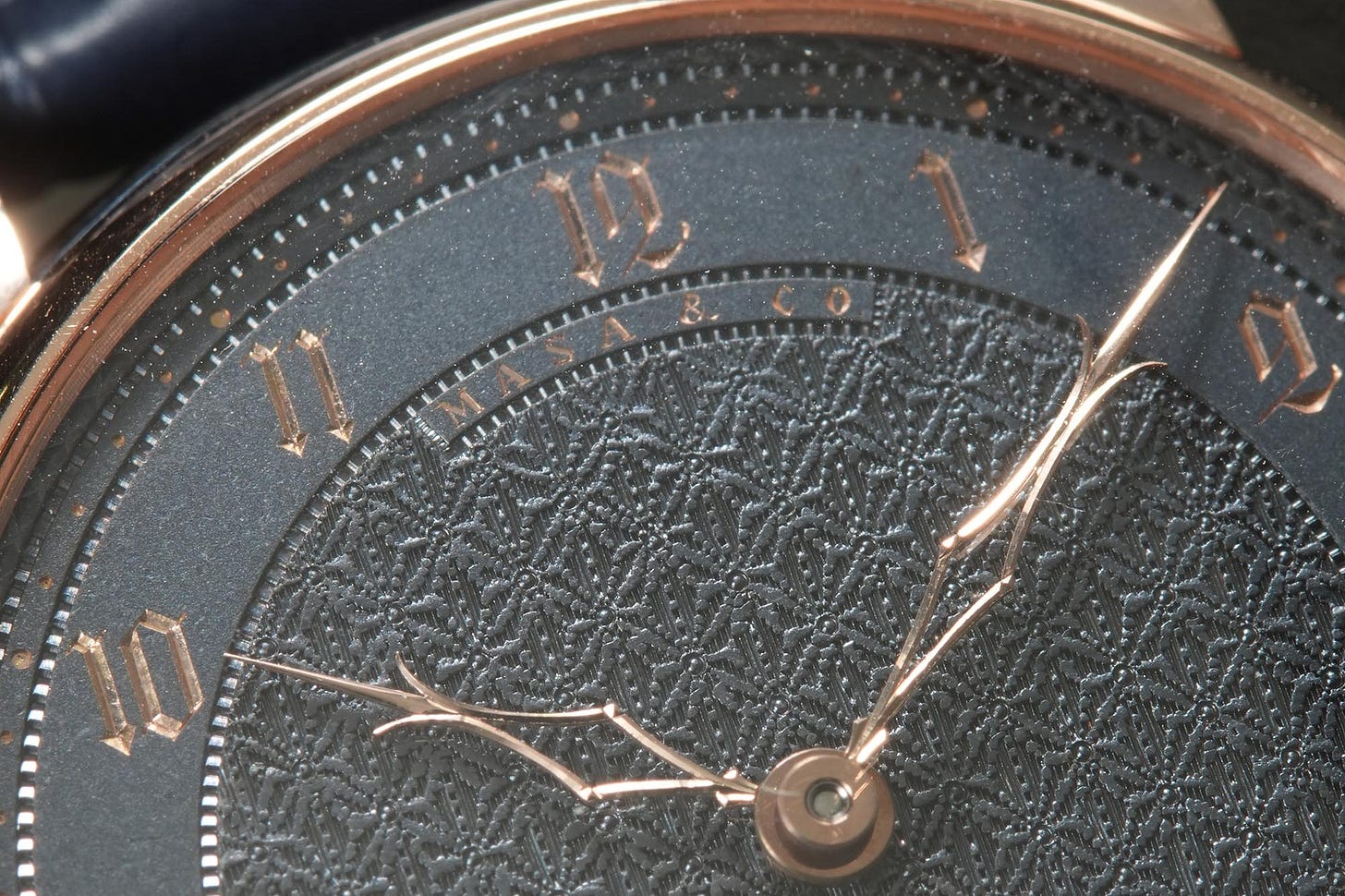

Designed entirely by Engraver K, who uses a special Japanese craft technique:

Engraved dial

Burnished “fabric-like” textures

A mixture of Japanese and Western techniques (e.g., Yoshi machine)

I wanted to introduce Japanese craft to the world.

2. Nagi — “Calm Water of the Sea”

My first design.

I am a sea person — I dive, I go fishing, I drive a small boat every weekend for 25 years. One day I encountered an exceptionally calm sea — like a lake, no waves, no wind. I said: “I must express this calmness in a watch.”

Dial: Sterling silver plated with green gold. Individually made indexes A deceptively simple but technically complex structure.

3. Shikae — “Rough Water of the Sea”

Released this year. A contrast to Nagi.

Sterling silver Bombay dial. Texture created using a small piece of coal scratched by hand — impossible to duplicate exactly.

All handmade.

Movement Finishing Variations

All three MP models use the same MP1 movement, but with different finishing depending on the model.

Customization Policy

Adi: Can customers customise their watches?

Masa: We can do anything. But if we accept everything, we will get into trouble — too time-consuming. So usually everything is fixed. But if someone really wants something concrete, we can consider it. For example, we made a special Soko-ku for Marc Cho: White gold, Shakudo,Platinum hands

Because everything is made here, we can do most things — but we must choose carefully.

Another Series — Shinohara’s Work

Three additional models are made by Naiveta Shinohara, who joined 5 years ago.

He won the Lange & Söhne Watchmaking Contest — first Japanese man to win gold. They instantly hired him. Masa told him: “Do whatever you want. I won’t tell you anything except about money.”

He starts with ETA/Unitas but heavily modifies them: Makes mainplates and backplates. Makes wheels. Special balance. Uses original escapement parts

Three models, each different.

Model A = top model, almost entirely his creation

Model B2:

Production Capacity

Masa: We don’t plan numbers, but last year we made 12 watches. Maybe a little more this year. For now, 12 per year is the maximum.

New Project — The MP Tourbillon

Adi: You have a new tourbillon coming?

Masa: Yes. Not sure when it’s coming. We are working on the MP Tourbillon — using as many parts from MP1 as possible.Same size and thickness, fits in the same case. Prototype has been running for a while — about 70% done. Maybe ready next May. This has never been announced before.

Future Intentions

Adi: What are your future plans?

Masa: I say the same thing to everybody. We want to make a little more watches in 10 years — maybe 30 per year. But we can’t scale without lowering quality, so we won’t become big. I need more watchmakers, maybe more engravers. More models.

Shinohara is working on a new smaller movement next year. I want to enjoy making new things often. But I have no definite plan. I don’t know where I’m going.

Why This Location?

Masa: I always wanted to show the workbench to the public. Previous shops were too small or on the second floor. When I found this place 20 years ago, I moved instantly. I sit near the window. Kids look through the glass while I work. Maybe some will become watchmakers.

Engraver K also likes working near the window. It’s like restaurants with open kitchens — you can see how things are made. Most clients come here to pick up their watches; I show them the workshop. They know exactly how their watches are made.

Final Words

Masa: I welcome everybody who wants to see or order a watch. But please make an appointment.

Masa’s Pastime

More info on the company and their watches: Masa's Pastime - Official Website

Address: 2-35-11 Kichijoji Honcho, Musashino-shi, Tokyo, Japan

Phone +81 422-38-8744 Fax +81 422-38-8743